Wood Pallet Waste Recycling Machines Plastic Shredder Blades

Basic Info.

| Model NO. | XD800 |

| Knife Classification | Claw Knife Crusher |

| Knife Roll | Solid Knife Roller |

| Automation | Automatic |

| Computerized | Computerized |

| Certification | CE, ISO9001:2008 |

| Weight | 3300 Kg |

| Shredding Room Size | 800*430 mm |

| Color | Client′s Requirements |

| Thickness of Rotor Blades | 40mm |

| Qty of Rotor Blades | 20PCS |

| Speed | 15-24rpm |

| Diameter of Rotor | 285 mm |

| Usage | Waste Plastic Cusher |

| Product Name | Shreddder Machine |

| Function | Plastic Cutter Grinder Crusher Shredder Machine |

| Blades Material | SKD-11 |

| Keyword | Double Shaft Plastic Shredder |

| Application | Recycled Industry |

| Name | Plastic Shredder |

| Transport Package | Wooden Case or Film Package |

| Specification | 3200*1300*1950 mm |

| Trademark | S&K |

| Origin | China |

| HS Code | 8477201000 |

| Production Capacity | 100sets/Year |

Packaging & Delivery

Package Size 320.00cm * 130.00cm * 195.00cm Package Gross Weight 3200.000kgProduct Description

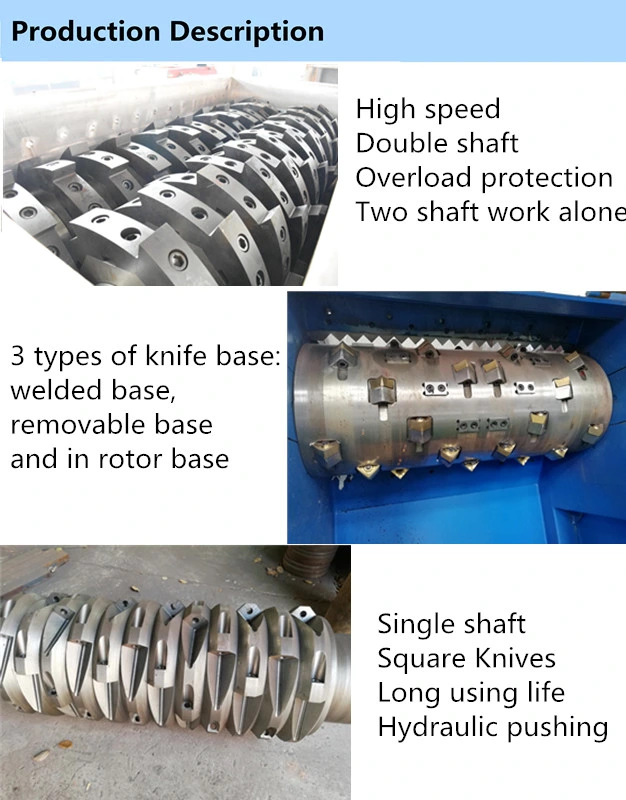

Wood pallet waste recycling machines plastic shredder bladesThe double shafts shredders have been designed for a wide ways of applications and industries, such as:shredding WEEE waste, scrap tires, packaging barrel, pallets, etc. Depending on input materials and the following process the shredded material can be used directly or go into the next step of size reduction. XD's serious double shaft shredder has two rotors built into the machine that rotate at low speeds, high torque and low noise. Adopt with microcomputer control system with function of start, stop, automatic reverse sensors to protect the machine against over loading and jamming.

Based on different materials, we design the special blades with different hooks, normally, we have single hooks blade, double hooks blades, four hooks blades and multi-hooks blades. Also the thickness of blades for different materials are different, the range is 10mm-80mm. We design single or multi-hooks of blades with different thickness for different materials.

Such as:

The 10 and 20mm thick blades are suitable for fragile materials such as medical packaging and electrical board.

The 40 and 50mm thick blades are widely used for various materials such as tires, plastic products, wood pallets, film and etc.

The 80mm thickness blades are used for shredding metal items or plastic and metal compounds such as refrigerator and drums, the blades can handle material up to 10mm in thickness.

1 | Model | XR600 | XR700 | XR800 | XR1000 | XR1200 | XR1500 |

2 | Diameter of rotor(22mm) | 280 | 280 | 400 | 400 | 400 | 450 |

3 | Speed of rotor(r/min) | 75-80 | 75-80 | 75-80 | 75-80 | 75 | 75 |

4 | Mesh size(mm) | 30-100 | 30-100 | 30-100 | 30-100 | 30-100 | 30-100 |

5 | QTY of rotary knives(pcs) | 26+4 | 33+4 | 34+4 | 48+4 | 64+4 | 76 |

6 | QTY of fixed knives(pcs) | 2 or 4 | 2 or 4 | 2 or 4 | 2 or 4 | 2 or 4 | 2 or 4 |

7 | Motor(kw) | 22 | 37 | 45 | 55 | 75 | 110 |

8 | Hydraulic motor(KW) | 2.2 | 2.2 | 3 | 4 | 5.5 | 7.5 |

Our kinds of raw material:

Packing&shipping :

Our service:

We will send our engineer instal our equipment in your factory and teach ur worker to learn and operate our equipment !

Company information:

S&K Machinery is a high-Tech company who is specializing in the R&D. The main products of S&K are :

- PP PE film/PET bottle pelletizing machine

- PP PE film/PET bottle recycling washing machine

- Plastic shredder /crusher /mixer strirrer and so on.

Each of these recycling machine can help the plastic industry to be high efficient , enenrgy saving, convenient and environment protection.

S&K Machinery,With its professional technical support and all full range service, is creating the new ,energy saving,high quality,high precision and high reliability machines with the help of the customers.

FAQ:

1. Q: Are you manufacture factory or a trader?

A: We are an industrial manufacture factory of plastic extrusion machinery for years, which locates in Zhangjiagang city, China.

2. Q: What's your payment term:

A: T/T 30% in advance & T/T 70% upon sending the copy of Bill of Lading, L/C 100%, or negotiate according to the order status.

3. Q: Can we visit your factory ?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case

4. Q: How do you make the quotation for clients?

A: The price depends on quality and performance but the clients should be satisfied first.

5. Q: Do you have any after-sale service ?

A: Yes,we have professional after-sale teamwork . any technical question could be solved in 24 hours by our after-sale teamwork.

6. Q: How do you install your equipment in our factory ?

A: We have professional after-sale &installation teamwork, we will arrange our engineer fly to ur factory install and teach ur labor .